How to Make Labels for Bottles

Bottle labels are the face of your brand and will be responsible for making a strong first impression in a competitive market.

But when it comes to bottling your product, it's not just about sticking to the basics. You must consider the bottle’s contours, consider how your labels will brave the elements, and tick all the boxes for specific industry standards and customer expectations. But where do you get started? Like anything else, it starts with a first draft.

What Should Be Included on a Custom Bottle Label?

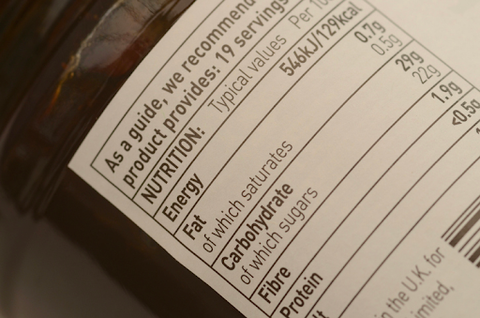

Depending on the type of custom bottle label you’re designing, there are a few different elements to consider. Whether you’re bottling beer, wine, honey, or condiments, your label should typically include net contents, nutritional information, allergens, company name, and ingredients.

Also, make sure to look up any legal labeling requirements related to your specific product. For example, most alcoholic beverages should be labeled with alcohol by volume (ABV). It's essential to adhere to standards like these to ensure your product is not just appealing but also compliant with TTB regulations.

How to Design a Label for a Bottle

From the shape and font to the color of your label, the design of your bottle label should capture the essence of your brand and appeal to your target audience. The right font makes all the difference and significantly influences your label's readability and emotional impact. A classy script might say you're all about luxury, while a bold, modern font could show off your brand's innovative edge.

Choosing the color scheme is all about feelings. A deep blue can calm your customers, making them trust you, while a vibrant red screams excitement. And the label shape is the frame of your masterpiece, fitting your bottle just right and telling your story at a glance. Imagine a traditional oval label on a wine bottle, exuding class, or a funky, asymmetrical shape on a craft beer, hinting at the bold flavors inside. It's all about matching these elements to the vibe you're aiming for.

4 Considerations for Bottle Labels

From material to label type, making a label requires a series of choices that can significantly impact your product's presentation and appeal on the shelf. Let’s explore the top considerations for how to design a label for a bottle:

Bottle Label Material

When selecting materials for your labels, think about what environment they'll be living in. Waterproof labels are ideal for items that may encounter moisture, oils, or chemicals, ensuring longevity and maintaining appearance.

For example, anything you’d throw in the fridge, like a cold beverage or condiment, should probably get the waterproof treatment. On the other hand, paper roll labels suit dry environments best and can come in matte or gloss finishes, depending on your preference. Matte paper, in particular, is optimal for labels requiring handwritten additions, providing a non-glossy surface for better ink adhesion and readability.

Label Size

Getting the size of your label just right is like tailoring the perfect outfit for your bottle. It has to fit snugly, not too tight or too loose, to show it off properly. Sizing labels precisely enhances your product's aesthetic appeal and makes the label easy to see and read. Remember, measure twice and cut (or in this case print) once.

Quantity of Labels

Printing a lot of labels all at once is often more efficient and cost-effective than ordering only a handful. It’s also always a good idea to order a few more than you actually need so you'll have extra in case of mess-ups.

This ensures flexibility for small businesses and personal projects, allowing you to start small while still benefiting from high-quality, custom labels tailored to your specific needs.

Label Types

Spin the wheel of labels: roll, sheet, or cut-to-size, based on what your project's vibe and wallet say. Roll labels are ideal for larger, ongoing needs due to their ease of application and storage, while sheet labels offer convenience for smaller projects or manual applications. Cut-to-size labels provide a versatile option for varied packaging designs and one-off uses.

How to Choose a Bottle Label Material

You have two main choices when selecting a label material: paper or waterproof labels. Paper labels are cost-effective and available in matte or glossy finishes but are not water-resistant. This means they can become discolored when accidents and spills happen. Although, as previously mentioned, paper labels are easy to write on for that personal touch.

On the flip side, waterproof labels (made from polypropylene) offer durability and resistance to spills but are slightly more costly because of this. However, investment in waterproof labels pays off in the long run by preserving the label's appearance and integrity, even in challenging conditions.

How to Apply a Custom Bottle Label

There are a few key steps to applying your custom label with precision. First, start with a clean bottle surface to avoid any dirt or grease that could keep it from sticking. After cleaning, allow the surface to fully dry to ensure optimal conditions.

Before applying your label, accurately measure the placement to ensure a centered alignment that lines up with the design you had in mind. Apply firm pressure across the entire label to eliminate air bubbles and secure it firmly to the bottle. Applying your label smoothly and carefully shows the customer you’re committed to quality in every aspect of your brand.

Create Your Own Bottle Labels with Stomp

Custom bottle labels are a powerful tool for distinguishing your products and telling your brand's story. However, designing them is an art that requires creativity and attention to detail. But don’t fret because Stomp is here to help you craft luminous labels!

Get started with our easy-to-use design tool and create custom labels that capture the essence of your brand and resonate with your customers.

- Nashira Edmiston